Unlocking Root Causes: The Power of the Ishikawa Diagram

Ever feel like you're constantly putting out fires without ever addressing the underlying issues? Like a leaky faucet, problems keep dripping back, disrupting your workflow and draining your resources. The Ishikawa Diagram, also known as the fishbone diagram or cause-and-effect diagram, is a powerful visual tool that helps you dive deep and uncover the root causes of these recurring problems. It's like having a roadmap to navigate the complex web of factors contributing to an issue, allowing you to address them strategically and prevent future occurrences.

The Ishikawa Diagram isn't about quick fixes; it's about getting to the heart of the matter. This tool provides a structured approach to brainstorming and analyzing potential causes, moving beyond superficial symptoms and digging into the underlying systems and processes that need attention. Whether you're dealing with a manufacturing defect, a customer service complaint, or a project delay, the fishbone diagram can help you unravel the complexity and find lasting solutions.

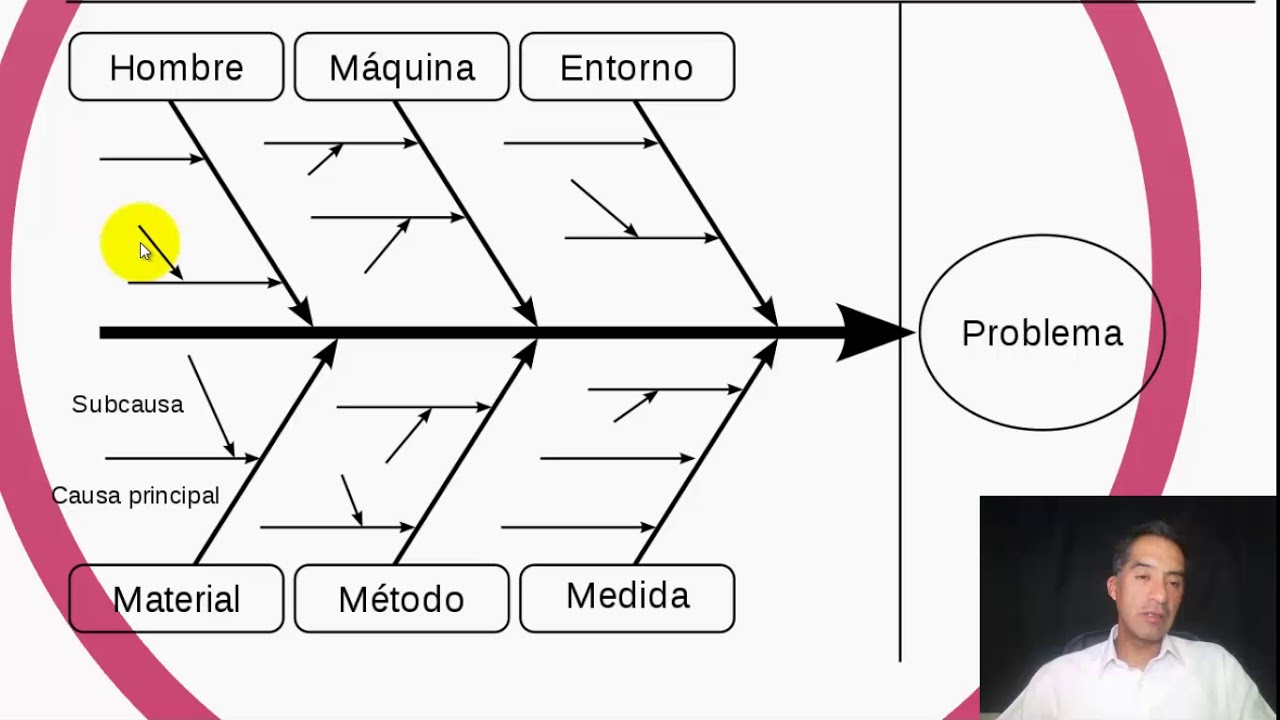

So, what exactly is the purpose of an Ishikawa Diagram? It serves as a visual representation of the various potential causes contributing to a specific problem or effect. Imagine a fish skeleton: the head represents the problem, and the bones branching out represent the different categories of potential causes. By systematically exploring these categories, you can pinpoint the factors that are most likely contributing to the issue.

The Ishikawa Diagram's effectiveness lies in its collaborative nature. It's a tool that encourages teamwork and diverse perspectives. By bringing together individuals from different departments or with varying expertise, you can leverage a collective understanding of the problem and generate a more comprehensive list of potential causes. This collaborative approach fosters buy-in and ownership, leading to more effective solutions.

This visual tool was developed by Kaoru Ishikawa in the 1960s while working at Kawasaki Heavy Industries in Japan. Originally used in quality control within the manufacturing industry, the Ishikawa Diagram has since been adopted across various sectors, from healthcare to education, proving its versatility in tackling diverse challenges. Its continued use speaks volumes about its effectiveness in problem-solving and process improvement.

The diagram's core function is to facilitate brainstorming sessions and organize the potential causes of a problem into categories. Common categories include: Machine (equipment), Method (processes), Material (raw materials, consumables), Man (people involved), Measurement (data collection, analysis), and Environment (surrounding conditions). These categories can be adapted to fit the specific context of the problem being analyzed.

Benefits of using an Ishikawa Diagram include: improved teamwork and communication, identification of root causes and not just symptoms, and a structured approach to problem-solving. For example, a delayed project might be traced back to unclear communication (Man), inadequate resources (Material), or a flawed project plan (Method). Identifying the specific cause within each category allows for targeted interventions.

To construct a diagram, begin by clearly defining the problem. Then, brainstorm potential causes, categorizing them under relevant headings. For each cause, ask "Why?" repeatedly to uncover deeper contributing factors. This "5 Whys" technique helps drill down to the root cause.

Advantages and Disadvantages of Ishikawa Diagrams

| Advantages | Disadvantages |

|---|---|

| Visualizes complex relationships | Can become overly complex for multifaceted problems |

| Facilitates brainstorming and collaboration | Requires experienced facilitation to avoid bias |

| Identifies root causes, not just symptoms | Doesn't provide solutions, only identifies potential causes |

Best practices include: focusing on one problem at a time, involving a diverse team, using the 5 Whys technique, and prioritizing identified causes based on their potential impact.

A real-world example could involve analyzing customer complaints about long wait times. Using the diagram, the team might identify contributing factors such as insufficient staff (Man), inefficient scheduling software (Machine), or unclear communication about wait times (Method).

Challenges in using the Ishikawa Diagram can include difficulty in reaching consensus on causes and the potential for overlooking less obvious factors. Solutions include involving a skilled facilitator and encouraging open communication.

FAQs include "What are the main categories?", "How do I choose the right categories?", and "How do I use the 5 Whys technique?". These questions can be easily addressed with clear explanations and examples.

Tips and tricks for using the Ishikawa diagram effectively include using sticky notes to facilitate brainstorming, clearly defining the problem statement, and ensuring active participation from all team members.

In conclusion, the Ishikawa Diagram serves as a valuable tool for anyone looking to delve deeper into problem-solving. It allows for a structured approach to identifying root causes, promoting collaboration, and driving meaningful improvements. By understanding its purpose, benefits, and practical applications, individuals and organizations can unlock its full potential and move beyond superficial fixes to address the core issues impacting their processes and performance. Whether you're a project manager, a quality control specialist, or simply someone looking to improve their problem-solving skills, the Ishikawa Diagram offers a powerful framework for achieving lasting results. Start using it today and experience the transformative power of getting to the root of the problem.

Decoding your paycheck understanding cara kiraan gaji malaysia

Unlocking homeownership navigating a bank of america home loan application

Unlocking the secrets of quinte du jour zone turf videos