Understanding Liquid Ring Vacuum Pumps

Ever wondered how some industrial processes achieve such efficient vacuum conditions? The answer often lies in the ingenious mechanism of the liquid ring vacuum pump. This article delves into the fascinating world of these pumps, exploring their operational theory and practical applications.

Understanding the liquid ring vacuum pump's functionality is crucial for anyone involved in industries requiring vacuum systems. Whether you're an engineer, technician, or simply curious about this vital technology, this guide will equip you with the knowledge to appreciate its versatility and effectiveness.

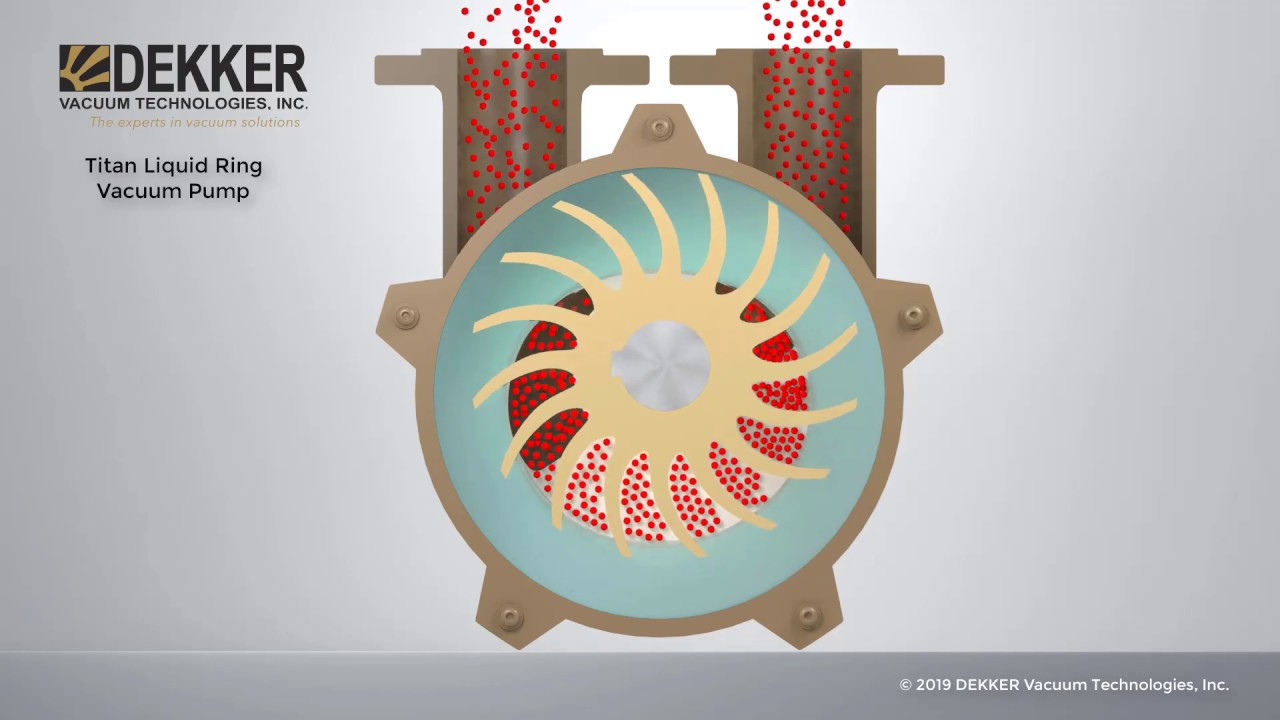

Imagine a spinning rotor within a cylindrical casing, partially filled with a service liquid, typically water. This eccentrically positioned rotor creates a rotating ring of liquid that forms the heart of the pump's operation. As the rotor spins, the liquid ring creates expanding and contracting chambers, effectively drawing in gas and subsequently compressing and discharging it.

The "liquid ring vacuum pump working principle" is often detailed in PDF documents, providing comprehensive diagrams and explanations. These resources are invaluable for grasping the intricacies of the pump's design and operation. Searching for "liquid ring vacuum pump working principle pdf" will lead you to a wealth of information, from manufacturer manuals to academic papers.

A deep dive into the mechanics of these pumps reveals a clever interplay of fluid dynamics and mechanical engineering. The liquid ring acts as a sealant and a piston, simultaneously creating the vacuum and compressing the extracted gases. This simple yet elegant design is responsible for the pump's robust performance and reliability across diverse applications.

The history of liquid ring vacuum pumps traces back to the early 20th century, with their initial applications focused on handling condensable vapors. Over time, advancements in design and materials have broadened their use across various industries, including chemical processing, power generation, and pharmaceutical manufacturing. Their ability to handle wet gases and vapors sets them apart from other vacuum pump technologies.

One key aspect of understanding the "liquid ring vacuum pump working principle" is recognizing the role of the service liquid. This liquid, often water, not only seals the pump but also cools and condenses the process gases. This inherent cooling capability makes them particularly suited for applications involving hot or corrosive gases.

A significant benefit of liquid ring vacuum pumps is their tolerance to liquid ingestion. Unlike other vacuum pumps that can be damaged by liquids, these pumps can handle small amounts of liquid carryover without compromising performance. This characteristic makes them ideal for applications where liquid entrainment is unavoidable.

Another advantage is their relatively simple design and maintenance. Compared to other vacuum pump technologies, liquid ring pumps have fewer moving parts, reducing the likelihood of mechanical failures and simplifying maintenance procedures.

Their inherent ability to handle a wide range of gas compositions, including wet and corrosive gases, makes them highly versatile. This adaptability allows them to be deployed in diverse industrial settings, from handling chemical vapors to extracting gases in paper mills.

Advantages and Disadvantages of Liquid Ring Vacuum Pumps

| Advantages | Disadvantages |

|---|---|

| Handles wet and corrosive gases | Lower ultimate vacuum compared to other technologies |

| Tolerant to liquid ingestion | Requires a continuous supply of service liquid |

| Simple design and maintenance | Can be less energy-efficient than other pumps |

For optimal performance, ensure the service liquid is clean and at the correct level. Regularly inspect the pump for wear and tear, and adhere to the manufacturer's recommended maintenance schedule. Understanding the "liquid ring vacuum pump working principle pdf" will help you troubleshoot potential issues and optimize performance.

Common challenges include maintaining proper liquid levels, preventing cavitation, and ensuring efficient sealing. Regular maintenance and proper operation are key to overcoming these challenges and ensuring the long-term reliability of the pump.

In conclusion, the liquid ring vacuum pump offers a reliable and versatile solution for various vacuum applications. Its unique operating principle, utilizing a rotating liquid ring, enables it to handle diverse gas compositions and operating conditions. By understanding the "liquid ring vacuum pump working principle pdf", users can effectively implement and maintain these pumps for optimal performance. From chemical processing to power generation, these robust machines play a critical role in countless industrial processes. Investing time in understanding their functionality is crucial for maximizing their benefits and ensuring long-term, efficient operation. Delve deeper into the available resources and unlock the full potential of your liquid ring vacuum pump system.

Streaming smackdown your guide to watching wwe online

Will kingdom of the planet of the apes rule the box office

Fantasy city names generator your portal to imaginary metropolises