Keep Your Mercury Outboard Pumping: The Impeller Kit Deep Dive

Ever wondered what keeps your Mercury outboard's heart beating? It's not magic, it's a crucial component called the impeller. This little rubber wonder circulates vital cooling water through your engine, preventing overheating and catastrophic damage. Ignoring this small but mighty part can lead to costly repairs, leaving you stranded on the water. This deep dive into the world of Mercury outboard impeller kits will equip you with the knowledge you need to keep your engine purring.

The impeller, housed within a water pump, is a rotating component with flexible blades. As it spins, it creates suction, drawing water from the surrounding environment and pushing it through the engine's cooling system. This continuous flow of water absorbs heat generated by the engine's combustion, maintaining a safe operating temperature. Without a functioning impeller, your outboard is at risk of overheating, potentially leading to warped heads, seized pistons, and a hefty repair bill.

The history of the outboard motor impeller is intertwined with the evolution of outboard motors themselves. As engines became more powerful and compact, the need for efficient cooling systems grew, leading to the development of the impeller-based water pump. Today, it's a standard component in virtually all outboard engines, a testament to its effectiveness and reliability.

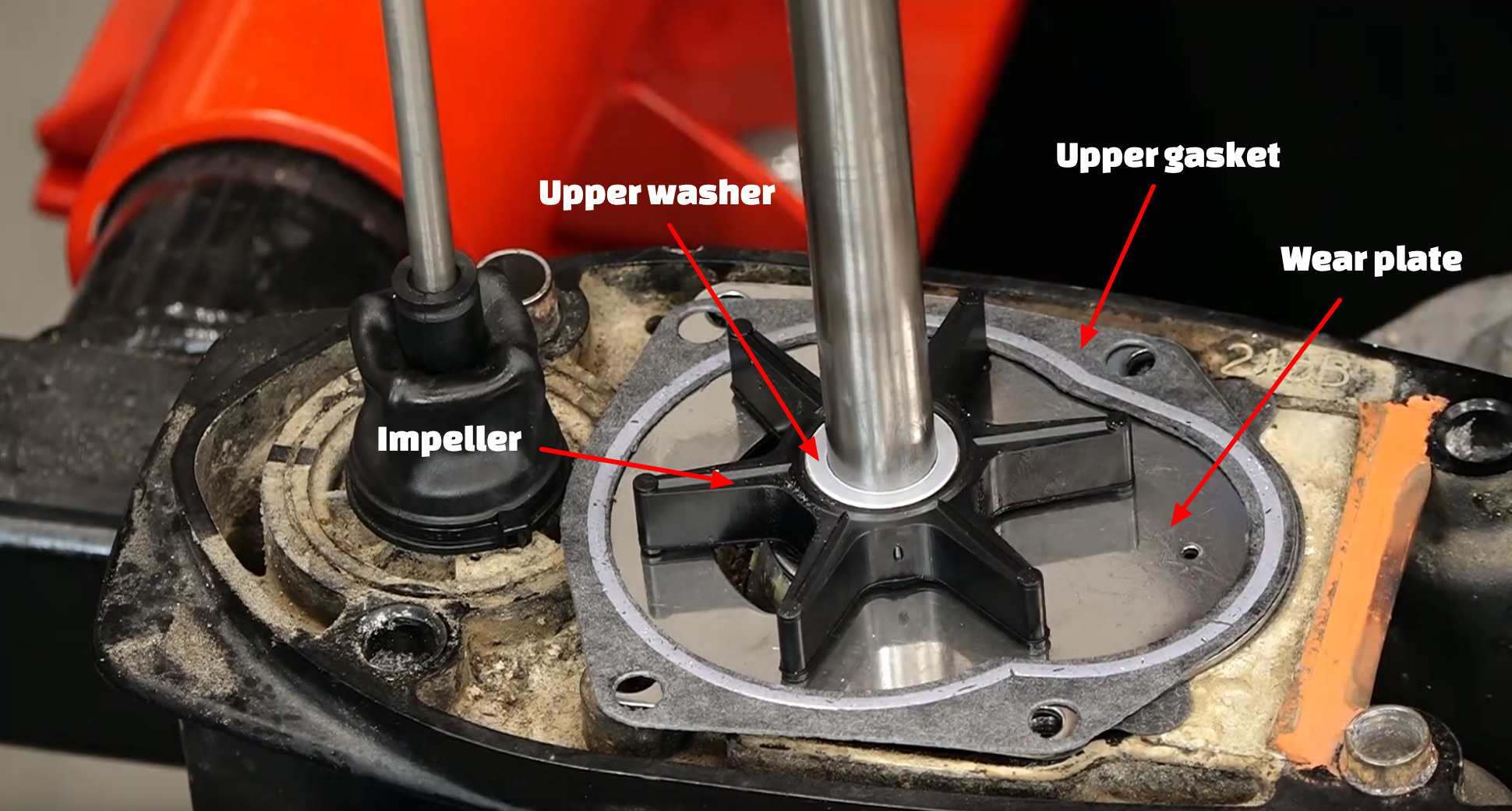

Mercury outboard impellers, specifically designed for their engines, come in various sizes and configurations depending on the horsepower and model. A Mercury outboard impeller kit typically includes the impeller itself, a housing gasket, and various seals. Sourcing the correct kit for your specific engine is crucial for optimal performance and longevity. This information can usually be found in your engine's service manual or by consulting a Mercury dealer.

One of the main issues associated with Mercury outboard impeller kits, or rather, the impellers themselves, is their susceptibility to wear and tear. Being made of rubber, they are prone to degradation from heat, chemicals, and even prolonged periods of disuse. Regular inspection and replacement, typically recommended every year or two, are essential preventative measures.

A properly functioning impeller kit ensures optimal cooling, extending the life of your outboard. It also prevents overheating-related performance issues, allowing your engine to run at its peak. Finally, a good impeller kit provides peace of mind, knowing you're less likely to experience a cooling system failure on the water.

Before starting any work on your outboard, disconnect the battery. Locate the water pump, typically near the lower unit of the outboard. Remove the old impeller and housing, carefully inspecting for wear or damage. Install the new impeller kit, ensuring proper alignment and secure fastening. Reassemble the water pump and reconnect the battery.

Impeller Kit Checklist:

- Correct impeller kit for your Mercury outboard model

- Necessary tools (screwdrivers, wrenches)

- New gasket and seals

- Lubricant (if recommended)

- Container for old parts

Advantages and Disadvantages of Regularly Replacing Impeller Kits

| Advantages | Disadvantages |

|---|---|

| Prevents catastrophic engine failure | Cost of replacement parts |

| Ensures optimal cooling and performance | Time investment for DIY replacement |

| Extends engine life | Potential for incorrect installation if DIY |

Best Practices: 1. Replace your impeller kit annually or every two years. 2. Always use genuine Mercury parts. 3. Lubricate the impeller with water or glycerin before installation. 4. Inspect the housing for wear or damage. 5. Never run your outboard dry.

Real Examples: Imagine an angler losing a prized catch due to an overheating engine. Or a family's boating trip cut short by a cooling system failure. These scenarios, often caused by a failing impeller, highlight the importance of preventative maintenance.

Challenges and Solutions: One common challenge is difficulty removing the old impeller. Solution: Use a pair of needle-nose pliers. Another challenge is installing the new impeller without damaging it. Solution: Lubricate the impeller and carefully twist it into place.

FAQ:

1. How often should I replace my impeller? A: Annually or every two years.

2. What are the signs of a failing impeller? A: Overheating, weak water stream from tell-tale.

3. Can I replace the impeller myself? A: Yes, with the right tools and knowledge.

4. What is included in an impeller kit? A: Impeller, gasket, seals.

5. Why is it important to use genuine Mercury parts? A: For optimal performance and compatibility.

6. What can cause impeller failure? A: Heat, chemicals, age, running dry.

7. How can I prevent impeller problems? A: Regular replacement, proper winterization.

8. Where can I buy a Mercury outboard impeller kit? A: Mercury dealers, marine supply stores.

Tips and Tricks: Soaking the new impeller in warm water before installation can make it more pliable and easier to fit. Marking the direction of rotation on the old impeller before removal can help ensure correct installation of the new one.

In conclusion, the humble impeller kit plays a vital role in the health and performance of your Mercury outboard. Regular inspection and replacement, along with following best practices, can prevent costly repairs and ensure countless hours of trouble-free boating. Don't underestimate the importance of this small but crucial component. Investing in a quality Mercury outboard impeller kit and adhering to a preventative maintenance schedule is an investment in your engine's longevity and your peace of mind on the water. Taking proactive steps to maintain your impeller will protect your investment and allow you to enjoy your time on the water without the worry of unexpected breakdowns. Don't wait for a failure to happen; make impeller maintenance a regular part of your boating routine. Your Mercury outboard will thank you.

Unlocking liaras heart your mass effect 1 romance guide

Bmw f80 m3 signal green the ultimate guide

The enduring allure of butterfly and flowers tattoo stencils