Automatic Bilge Pump Wiring: Your Boat's Unsung Hero (and How to Wire It Right)

So, you're a boat owner. Congratulations! You've joined the ranks of those who appreciate the open water, the wind in your hair, and the thrill of adventure. But owning a boat is more than just sunshine and smooth sailing. It's about responsibility, maintenance, and, yes, understanding the nitty-gritty details like automatic bilge pump wiring. Because let's be real, nobody wants a sunken investment, right?

An automatic bilge pump is like your boat's silent guardian, tirelessly working to keep you afloat. It's the unsung hero that prevents a minor leak from turning into a full-blown disaster. But this crucial piece of equipment is only as good as its wiring. A faulty automatic bilge pump wiring diagram can leave you high and dry (literally), so understanding the ins and outs is paramount.

Understanding an automatic bilge pump wiring schematic isn't rocket science, but it does require some basic electrical know-how. This article will break down the essentials, from basic connections to more complex setups. We'll explore the different components, the logic behind the wiring, and the crucial safety considerations you need to keep in mind. Think of it as your ultimate guide to keeping your vessel afloat and your peace of mind intact.

Why should you care about a bunch of wires and connections? Because a correctly wired automatic bilge pump can be the difference between a minor inconvenience and a major catastrophe. A manual bilge pump requires your constant attention, but an automatic system gives you the freedom to enjoy your time on the water without constantly checking for water accumulation. It's like having a little automated sentry in your bilge, keeping watch while you relax.

While the specifics of an automatic bilge pump setup can vary based on the size and type of your vessel, the fundamental principles remain the same. A float switch activates the pump when water reaches a certain level, and the pump then expels the water overboard. The wiring diagram dictates how these components connect, ensuring the system functions as intended. This seemingly simple setup is vital for maintaining the safety and integrity of your boat.

The history of automatic bilge pumps parallels the development of electrical systems in boats. Before electricity, manual pumps were the only option. The introduction of electric pumps revolutionized boat safety. Understanding the wiring diagram ensures your pump operates reliably. Miswiring can lead to pump failure or even electrical hazards.

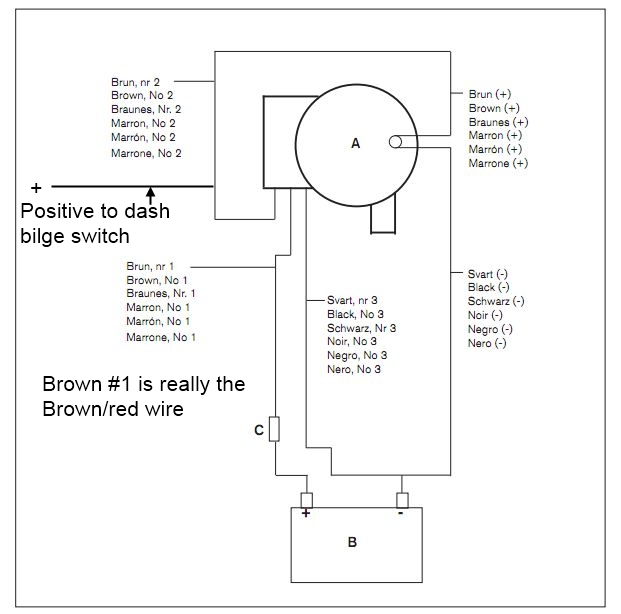

A typical automatic bilge pump wiring diagram involves a power source (usually the boat's battery), a fuse, a float switch, and the pump itself. The float switch acts as the trigger, activating the pump when water levels rise. The fuse protects the circuit from overloads. The power flows from the battery, through the fuse, to the switch, and finally to the pump.

Benefits include automatic water removal, peace of mind, and prevention of sinking. For example, if you encounter unexpected heavy rain, the automatic pump will kick in without your intervention, keeping the bilge clear. This automated operation offers invaluable peace of mind, especially when you're away from the boat.

Advantages and Disadvantages of Automatic Bilge Pumps

| Advantages | Disadvantages |

|---|---|

| Automatic operation | Requires electrical power |

| Increased safety | Can fail if not maintained |

| Peace of mind | Initial cost higher than manual pumps |

Best Practices: 1. Use marine-grade wiring. 2. Install an inline fuse. 3. Test the system regularly. 4. Inspect the float switch for debris. 5. Ensure proper wire connections.

FAQs: 1. What size pump do I need? (Depends on boat size) 2. How often should I test the pump? (At least monthly) 3. What type of fuse should I use? (Marine-grade) 4. Can I install it myself? (Yes, with proper knowledge) 5. What if the pump doesn't turn on? (Check the fuse, switch, and wiring) 6. Where should I mount the float switch? (In the lowest part of the bilge) 7. How do I maintain the pump? (Clean the screen regularly) 8. Can I wire multiple pumps together? (Yes, with specific wiring configurations)

Tips: Regularly inspect and clean the float switch to prevent debris from interfering with its operation. Use waterproof connectors to prevent corrosion. Double-check all wiring connections to ensure a secure and reliable system.

In conclusion, a correctly wired automatic bilge pump is an essential safety feature for any boat owner. Understanding the automatic bilge pump wiring diagram empowers you to maintain this crucial system, preventing potentially disastrous situations. From basic connections to troubleshooting tips, this article has provided you with the knowledge necessary to keep your boat afloat and your adventures worry-free. Don't underestimate the importance of a properly functioning bilge pump; it's a small investment that can save you a lot of heartache (and money) in the long run. Take the time to understand your system, perform regular maintenance, and enjoy the peace of mind that comes with knowing your vessel is protected. By prioritizing your bilge pump's functionality, you're not just protecting your boat; you're ensuring the safety and enjoyment of everyone on board. Now get out there and enjoy the water!

Wanted poster templates online design your own wild west style

The quiet elegance of pecan sandie a behr paint exploration

Transform your workspace with behr office paint